Rohde & Schwarz solution

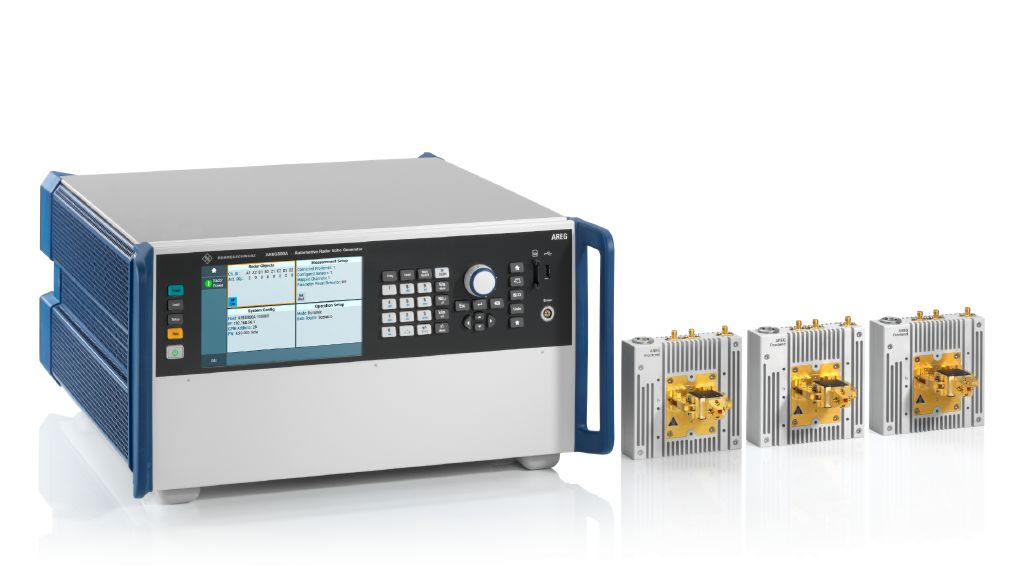

With precision engineering, advanced technology and an optimized feature set, the AREG800A R&S®AREG-P fixed product configuration versions are the perfect choice for ensuring accuracy, efficiency and reliability in the end-of-line production testing process for automotive radar sensors.

The R&S®AREG-P solutions from Rohde & Schwarz ensure a seamless transition of radar sensors from R&D to production for tier 1 suppliers that develop automotive radars using the AREG800A automotive radar echo generator.

Rohde & Schwarz production solutions offer both technology and business benefits. Technology benefits include automotive radar echo generator (AREG) technology transition, variable object distance, waveform agnostic, minimum distance equal to air gap and compact antenna test range (CATR) reflector technology transition for vertical and horizontal systems. Among the business benefits these solutions offer are capital expenditure (CAPEX) reduction and distribution, operating expenses (OPEX) reduction and optimization, time to market (TTM) minimization, failure risk reduction, production process optimization and improvement of the connection between R&D and production.