Enhancing your RF & Microwave testing

Analyze and validate your RF systems with our comprehensive RF testing solutions at Rohde & Schwarz.

Radio Frequency (RF) testing is a critical process for ensuring the performance of any RF system used in wireless, radar, satellite, automotive, and industrial applications, as well as in the building blocks and components that make up these technologies. It involves verifying frequency accuracy and stability in RF and microwave systems. This validation is essential throughout the entire product lifecycle, from development to manufacturing, as it helps identify any issue that could compromise the functionality and reliability of the device. Without precise measurement data, engineers risk costly design spins, delayed product launches, and failure to meet the stringent performance requirements of the latest wireless standards.

Radio frequency (RF) testing is essential to validate the capabilities and the performance of:

- Complete RF systems used in wireless, radar, satellite, automotive, and industrial applications.

- Individual building blocks and components that are integrated to construct these RF systems.

Recent advancements in RF technology are driving innovation across all applications. Key enhancements include:

- Expanded frequency range: Systems now address higher frequencies, reaching well into the THz spectrum.

- Broader signal bandwidth: Support for wider bandwidths enables increased data throughput and more precise positioning in sensing applications.

- Enhanced energy efficiency: Improvements at both the system level and within active components, such as amplifiers and RF frontends, help extend battery life and reduce heat dissipation.

- Miniaturization and integration: Multiple semiconductor technologies are now being combined into single components or modules, enabling more compact and versatile designs.

To effectively analyze and evaluate the performance of your RF systems, advanced radio frequency test and measurement equipment is essential. These forward-looking tools support the evolving demands of research, validation, and production – helping you stay ahead in today’s rapidly advancing RF landscape.

To address these challenges, we take various measures at Rohde & Schwarz

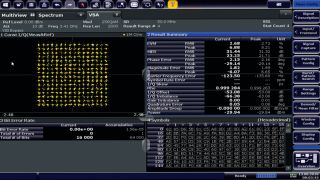

- Obviously enhancing and extending test solutions in frequency, bandwidth, sensitivity and functions with Rohde & Schwarz vector network analyzers, vector signal generators and signal and spectrum analyzers

- Working with partners to enable complete solutions for on-wafer and load pull applications for example for CW and modulated test scenarios

- Optimize test instrumentation for the different steps along the value chain, for example improved speed with the right level of capabilities for validation and production applications as offered in the R&S ZNB3000 vector network analyzer or the R&S PVT360A performance vector tester

- Find out more about the different instrument categories of our RF testing equipment at Rohde & Schwarz.